Behind the Fabric: Vitale Barberis Canonico Wool Flannel

Lifestyle

By: Olof Enckell, Collection Manager • 6 min

With more than 360 years of expertise, Vitale Barberis Canonico stands as a cornerstone of Italian textile heritage. For the debut of Eton’s Soft Jackets, we journeyed to the legendary Biella mill to uncover how one of the world’s most renowned wool flannels is created—from raw fiber to refined fabric.

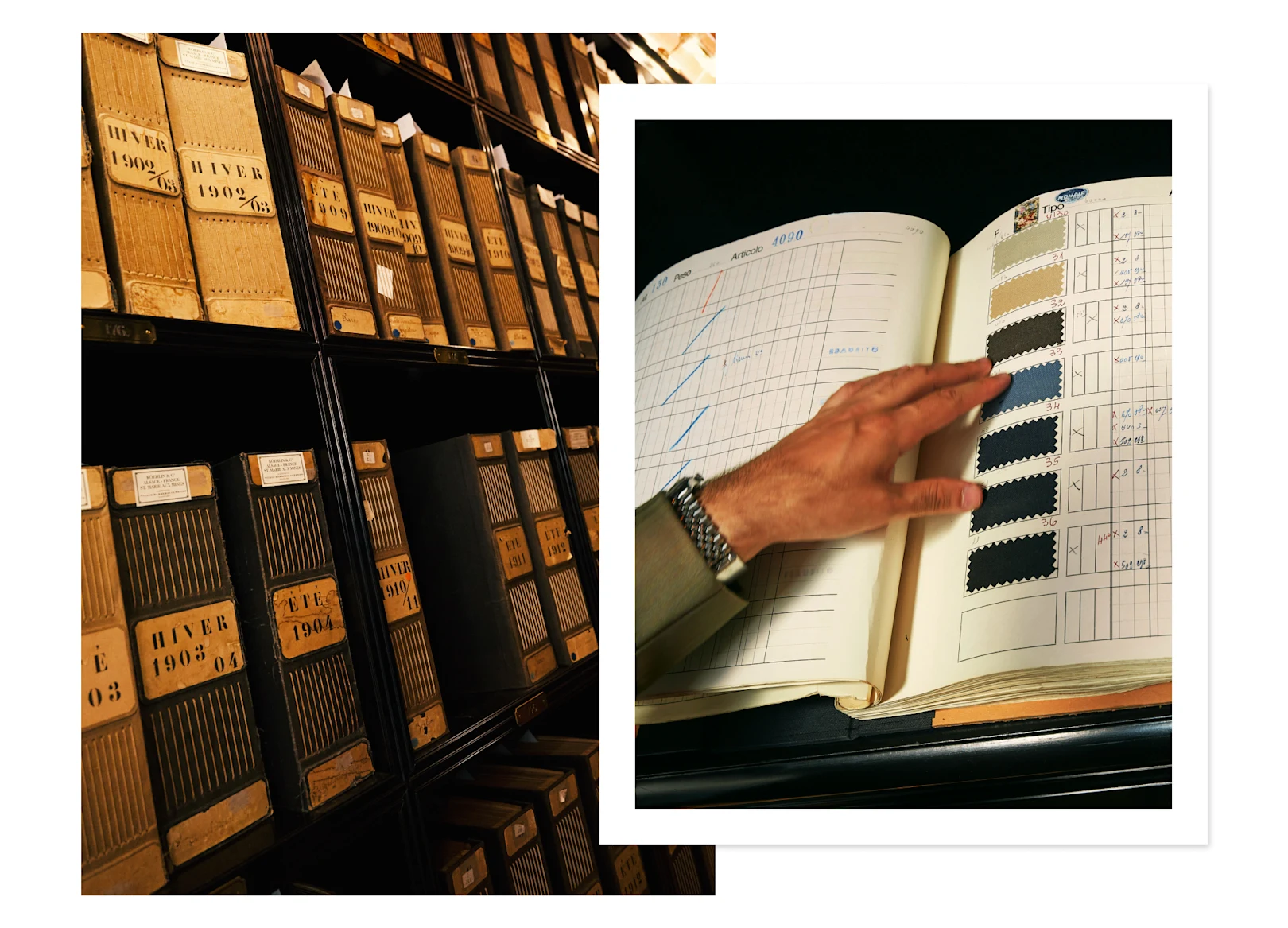

The story of Vitale Barberis Canonico began in 1663, when founder Ajmo Barbero presented a piece of dyed grey wool to the Duke of Savoy. His mastery of color quickly earned renown, laying the foundation for a textile house that would endure across centuries. As generations followed, VBC grew by embracing innovation early — importing knowledge from Britain’s textile revolution and later pioneering the use of electricity in the 19th century.

What has never changed is place. Since its inception, VBC has remained in Prativero, in the Biella region of northern Italy — a landscape whose rivers and alpine water have long been prized for textile making. Today, the mill is helmed by the 13th generation of the Barberis family. With 480 employees and an output of seven million meters of fabric annually, it stands as the largest mill in Biella, supplying everything from small bespoke ateliers to some of the world’s most established fashion houses.

For one of the jackets within Eton’s first collection of Soft Jackets, we chose one of VBC’s most celebrated fabrics: the Super 120’s wool flannel. Crafted from extra-fine merino wool sustainably sourced in Australia, it undergoes more than 200 meticulous steps before becoming the cloth tailored into a jacket. Each stage enhances the natural performance of merino—from breathability to resilience—while preserving a remarkably soft hand.

The process begins with washing and gilling the raw wool in Romagnano Sesia before it arrives at VBC’s Prativero facility for dyeing. Here, the fibers are top-dyed, meaning the wool is colored before being spun into yarn. This technique ensures exceptional colorfastness and allows different shades to be blended during spinning, creating the vivid mélange effects for which VBC flannel is known. In some cases, the mill uses a rare, century-old printing machine to apply geometric patterns directly to the wool tops—producing a uniquely dynamic depth of tone once the fibers are spun.

Unlike traditional flannel, which relies on carded wool, the Super 120’s is made with worsted wool. Carefully combed so the fibers align in the same direction, the result is a smoother, stronger yarn. Woven with double-twisted yarns, the cloth gains greater durability and natural wrinkle resistance. Significantly lighter than traditional wool flannels, it offers versatility beyond winter — ideal for year-round wear.

Once the yarns are spun, the warping process begins: thousands of threads are carefully aligned onto a beam to form the fabric’s vertical structure. Precision here is critical, setting the stage for the pattern and texture to come. In weaving, these warp threads are interlaced with the weft, guided by a complex system that creates the desired design.

At VBC, 100 state-of-the-art looms carry out this process—the majority enclosed in soundproof cabins. An innovation introduced by the mill, the cabins don’t affect efficiency or quality, but they reduce noise levels dramatically: from 100 decibels to 85, closer to the hum of city traffic than a factory floor. For the craftspeople who work here daily, it’s an uncommon commitment to workplace well-being.

After weaving comes the finishing—a decisive stage that transforms a coarse fabric into one with VBC’s signature buttery-soft hand. The newly woven cloth is washed with soap and the naturally pure waters that flow down from the Alps. This alpine water, with its uniquely low mineral content, has long been the Biella region’s secret to exceptional textiles. Today, VBC combines this natural resource with cutting-edge sustainability: ultrafiltration systems and ozone decolorization purify water from the dyeing process, allowing it to be reused while preserving its essential properties.

Throughout production, every meter of fabric is inspected for precision and consistency. The process culminates in a final visual review by VBC’s highly trained menders—specialists who spend over four years mastering their craft. With a discerning eye, they correct even the smallest imperfections, ensuring that only flawless cloth leaves the mill.

It’s this combination of centuries-old expertise, modern innovation, and uncompromising quality control that makes Vitale Barberis Canonico wool flannel a benchmark in fine textiles—and the perfect choice for Eton’s first Soft Jackets.